Tailor-made solutions

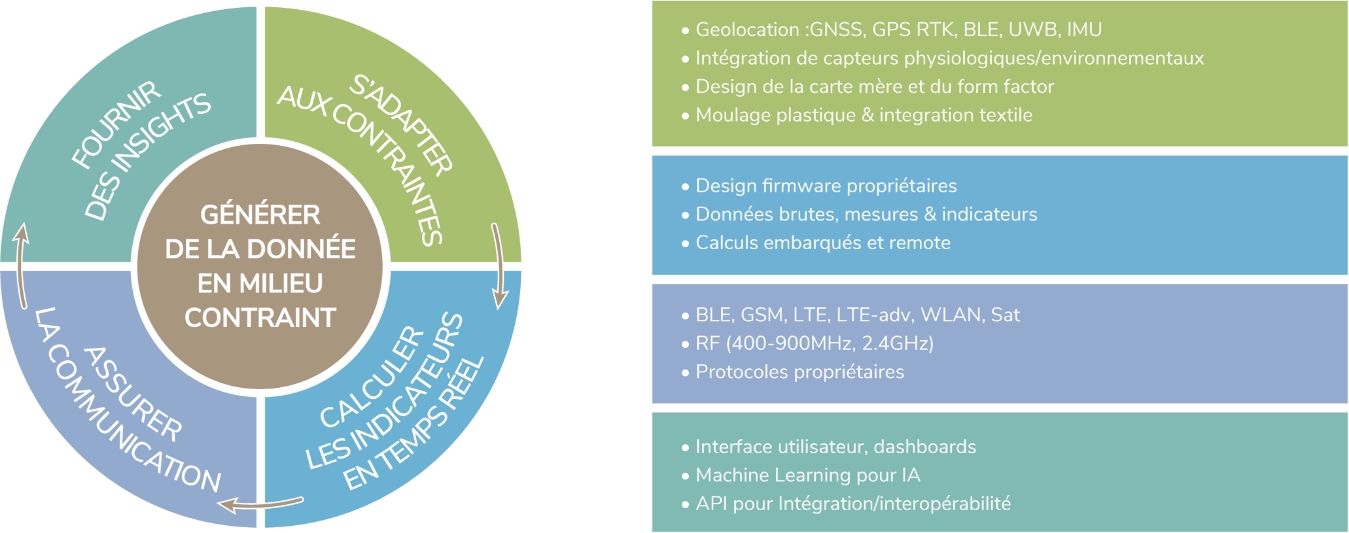

TRAAK develops, manufactures, and creates geolocation custom-made solutions entirely in-house and in France, to meet confidentiality and sovereignty requirements and to offer a solution when commercial solutions do not allow it.

TRAAK masters all communication systems (BLE, GSM, LTE, LTE-adv, WLAN, Satellite, RF), allowing us to meet the demands of the most challenging environments and complex specifications.

Submetric positioning of a crowd

Context

An immersive show at the roman amphitheatre antique of Orange,

offers the spectators, who are free to roam anywhere, a video & sound show with a 3D spatial sound atmosphere that changes radically based on position in the amphitheater.

Requirements were to position in real time with a sub-metric precision 300 visitors simultaneously while the system being integrated in a commercial standard sound headset.

A combination of a GNSS quad constellation solution with a custom made UWB protocol and high performance IMU has been developed. 25 UWB anchors were installated in the projectors.

Real-time submetric positioning of all 300 visitors with head orientation was achieved with miniaturization of the system for integration in commercial headphones.

Mining freight trains

Context

Mining often occurs in remote locations and very large freight trains are used for transporting minerals to treatment plants or ports over hundreds of km.

Pain point

No precise field information is available on the exact structure of the convoy which can make several stops to add/remove wagons. The client would like to have a better understanding of the convoy and its whereabouts. The remote location of the mines and of the railway tracks make it difficult to use simple tracking and cost effective solution.

Trackers positioned on each wagon creat a mesh network with previous and next wagon to generate a real time structure of the convoy communicating back to main gateway on the engine.

Dedicated RF protocols combined with GNSS /IMU data fusion. GSM/Sat communication to dedicated server.

Road convoy, production lines, logistic and production sites

Site protection

context

A secured site spanning tens of square kilometers receives dozens of visitors each day. After registering at the guard post, visitors are not always accompanied and are sometimes found in restricted areas.

pain point

Geolocate visitors outdoors using a tamper-proof, non-removable system. Define authorised or restricted zones per visitor with access to real-time data. Secure the generated data without using GSM or WiFi. Transmit alerts to a supervisor. TRAAK has no access to servers, hypervisor, or the site’s tactical maps

A waterproof, secure bracelet tracker issued at the security post. GNSS-based location with metric precision. Real-time communication to client servers allowing integration with a geo-referenced tactical map. Simple user interface with geofencing capabilities or predefined routes.

Quad-constellation GNSS, RF-band communication using a proprietary TRAAK protocol encrypted with RSA 128-bit, silicone-molded IP65 tracker, software with source code provided.

Security team tracking, employee location on construction sites, mines/energy, airports.

Person flow in healthcare

context

Hospitals or clinics receive hundreds of people daily. Needs and availability can change quickly due to emergencies, leading to delays and constant adaptation needs.

pain point

Managing emergencies requires constant adaptability. Delays must be handled promptly to avoid overcrowding in treatment rooms, excessive waiting times, and managing accompanying parties (ambulance/taxi/family). Critical medical equipment must be available on demand without delays.

Geolocate patients and critical equipment using an expandable, secure, and easy-to-implement technology. Set up a virtual queue system and equipment management.

BLE with proprietary communication independent of the hospital’s system.

Public service offices with appointments, management of corporate/university restaurants, industrial or strategic asset tracking.

High-risk work zones

context

Work zones or warehouses often have confined spaces where many vehicles and pedestrians are present.

Pain point

Close proximity between vehicles and pedestrians is inevitable in these mixed work zones, posing a significant accident risk. Working near machinery is often necessary, and proximity alarms are often disabled or ignored due to their inconvenience.

Predictive collision models using high-frequency sensors on vehicles and co-workers that trigger alarms only for those at risk. Alerts provide exact geolocation to a security control room, with interaction with the CAN bus possible.

HPv2 with RTK GPS, UWB, and a 9-axis inertial unit + predictive impact detection algorithm.

Use in logistics warehouses or production factories with high-risk machinery.

Medical Device Stock Management Situation

context

The medical device industry provides numerous references via temporary deposits at hospitals and clinics. Once products are used, they are replaced by the manufacturer, and consumables are invoiced. Stock management is the manufacturer’s responsibility.

Pain point

Stock management is done manually during visits by the manufacturer’s staff or a contracted company. Stock management is not automated, leading to discrepancies, billing delays, and low-rotation stock, which financially impacts the manufacturer.

Low-cost automated stock management across all sites. The solution detects product usage, enabling invoicing. It can be coupled with transport boxes for tracking shipments and automatically detecting contents.

Dedicated RF solutions + GPS if necessary. Integration with ERP and billing software.

Use for any type of logistics shipment. Addition of shock//temperature sensors.